Bilcare Research Website Konzept und Kalkulation - PAGE-AND-PAPER_

BlisBa

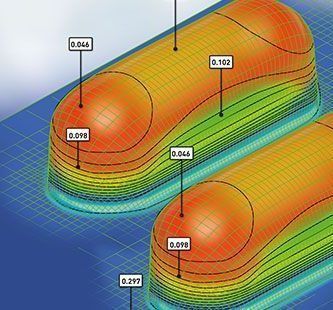

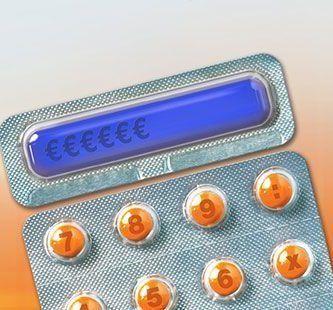

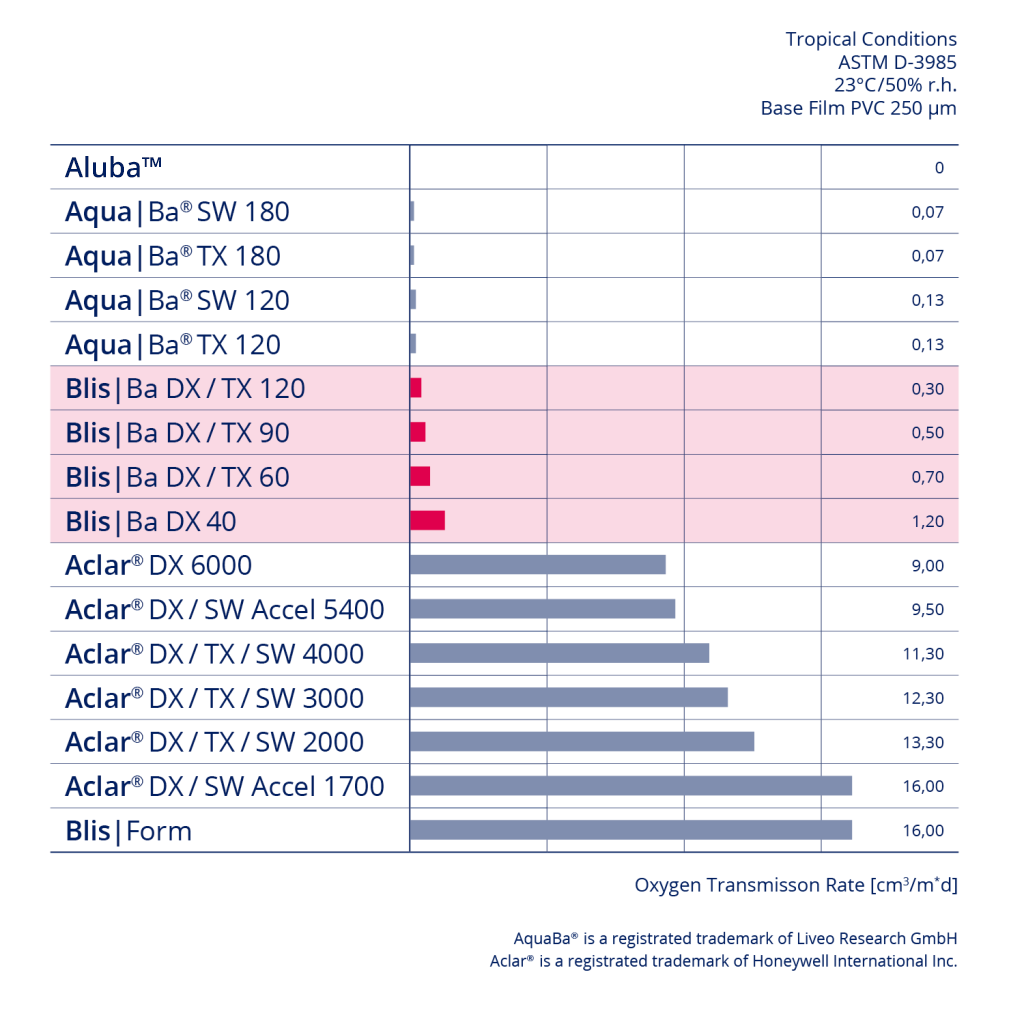

Using advanced coating technology, BlisBa is an economical option for a variety of barrier blister applications. Liveo Research’s proprietary PVC film, known for providing optimum thermoformability, is coated with a high barrier PVDC coating. This coating technology allows for the elimination of the traditional PE sandwiched layer, even at higher PVDC coating weights.

BlisBa DX, a two layer barrier film, is available with four standard PVDC coating weights to meet most barrier requirements. For those few applications that require a PE layer, we supply BlisBa TX. Our proprietary PVC film formulation makes BlisBa easily thermoformable at high speeds and reduced temperatures for high performance blister lines. We also offer a rigid PVC film for more specific blister designs. BlisBa is available either in a highly transparent, or opaque white finish.

Looking to switch? Liveo Research provides a variety of added value services to ease the transition away from lower performing films while maintaining vital barrier properties.

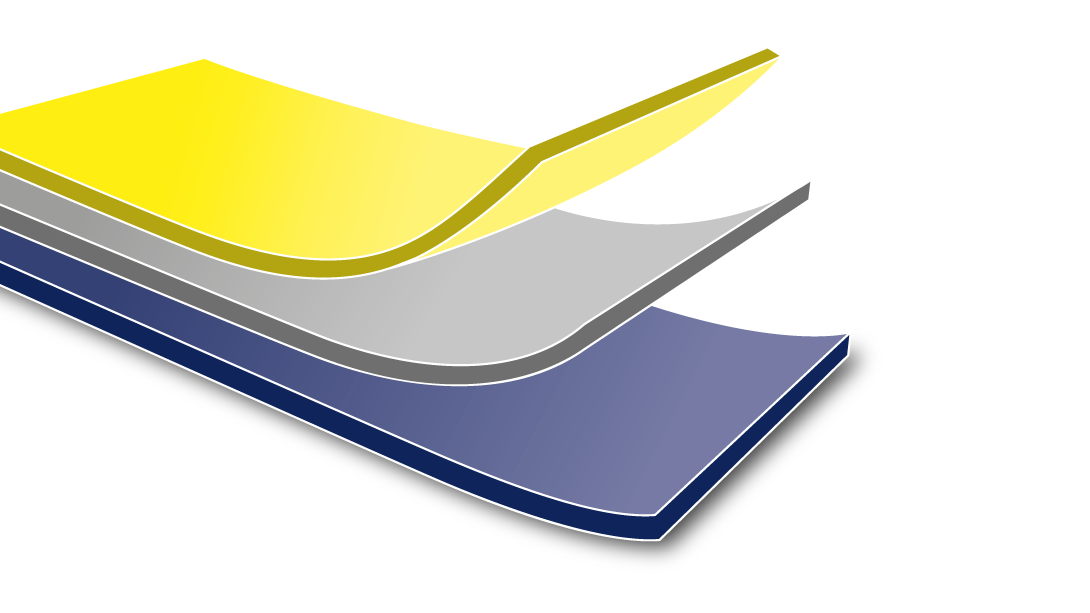

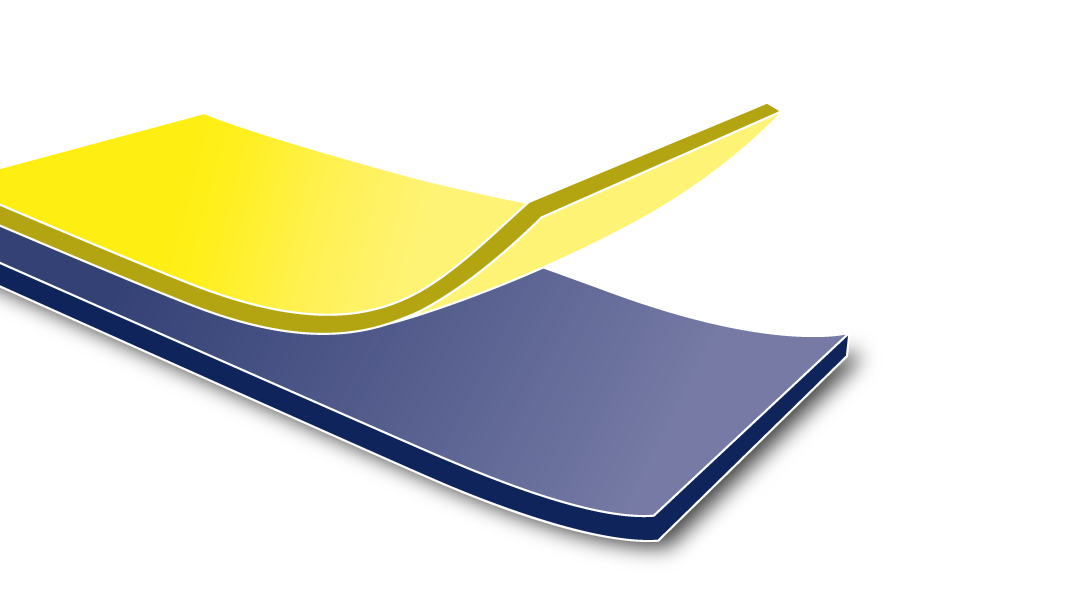

Three-layer "Triplex" structure of PVC/PE/PVDC

- Includes additional laminated intermediate PE layer with PVDC coating

- Additional coating weights available on request comparable BlisBa DX structure

- Energy efficient, shorter heating times with increased machine speeds

- Excellent layflat properties for a quality appearance

- Sealable with heat seal lacquers intended for PVC or PVC / PVDC

- Ideal product protection achieved by sealing PVDC coated side against blister lidding foil using heat seal lacquers intended for PVDC

Two-layer “Duplex” structure of PVC/PVDC

- Advanced PVDC coating technology eliminates need for additional flexible PE intermediate layer, even at high coating weights

- High water vapor and oxygen barrier (same as TX structure)

- Superior dimensional stability

- Homopolymer or copolymer formulations

- Energy efficient, shorter heating times with increased machine speeds

- Excellent layflat properties for a quality appearance

- Higher yield in comparison to equivalent TX structure making it a more cost effective barrier specification

- Sealable with heat seal lacquers intended for PVC or PVC / PVDC

- Ideal product protection achieved by sealing PVDC coated side against blister lidding foil using heat seal lacquers intended for PVDC

The Liveo +

- Outstanding customer service representatives

- Global and on-site application engineering support

- Local languages spoken by knowledgeable indigenous sales representatives

- Central point of contact for easy communication

- Low development costs

- Perfect product protection in respective climatic zone

- Avoidance of over packaging due to incorrect foil specification

- Reduction of waste, overpackaging and costs

- New film formulations developed in conjunction with customer input and requirements

Quality and Regulatory

- Liveo Research BlisBa films comply with global applicable regulatory standards

- Current valid EU Pharmacopoeia, USP section 661.1

- FDA 21 CFR

- EC 1935/2004, (EU) No. 10/2011, REACH - Regulation (EC) No. 1907/2006

- USDMF# 1081, Canadian DMF# 2017-093

- Comply with the Chinese Pharmacopeia and are registered at the CDE